Accuracy, productivity, and operational expense control are vital in any business, and even more so in the pharmaceutical industry. As for the cost, the right choice of machine can enhance productivity and accuracy while lowering operational costs. One of the most important components in pharmaceutical Production Line is the pill counting machine.

This piece of equipment, along with other components, allows for attention to detail which ensures that precision, efficiency and compliance are followed, as well as improving quality assurance while meeting regulation standards. In order to ensure that an organization’s objectives are met, their partners must be reliable as well. This guide suggests tips and tricks on how to choose the optimal pill counter machine.

Understanding the Role of Pill Counter Machines in Pharmaceutical Manufacturing

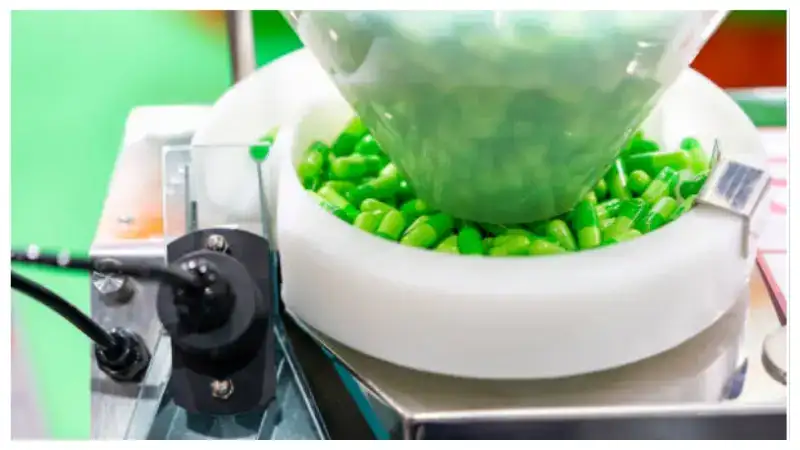

The machines are fundamental units designed to count and dispense tablets, capsules, and other solid dosage forms with high accuracy. Their use is common in the Production Line, packaging, and distribution of pharmaceuticals where counting has to be accurate. The main function is to make sure that a given number of pills are dispensed into bottles or packaging containers, minimizing deviations and meeting the demanding quality control standards set in place.

Pill counters have direct repercussions for the overall operational effectiveness of pharmaceutical firms since these highly accurate machines enable companies to maintain speed and accuracy throughout their production lines. These machines also reduce human error associated with manual counting of pills as well as lower the costs spent on labor. In addition, more sophisticated models of pill counters have better peripheral devices from pharmaceutical equipment manufacturers which enables smoother workflow and higher productivity. Automated systems with monitoring capabilities add value in terms of quality assurance and compliance tracking, as these can easily be documented and analyzed.

Key Features to Consider When Choosing a Pill Counter Machine

Selecting the right one requires a thorough understanding of your Production Line requirements. Several essential features must be considered to ensure the machine meets your needs and provides optimal performance. Firstly, accuracy and precision are the most critical factors. A high-quality one should be capable of accurately counting a wide range of pill sizes, shapes, and materials without deviation. This accuracy is essential for ensuring the correct dosage is dispensed and maintaining compliance with Good Manufacturing Practices (GMP).

Secondly, speed and throughput capacity must be evaluated. Pharmaceutical companies operating large-scale production lines need machines capable of handling high volumes without compromising accuracy. The machine designed by reputable pharmaceutical equipment manufacturers often come with adjustable settings that allow manufacturers to increase or decrease counting speed as needed. Another important consideration is integration capability. The machine must be compatible with other equipment within the production line, such as filling machines, tablet presses, labeling systems, and packaging units. Integration ensures a smooth, uninterrupted workflow that minimizes downtime and maximizes productivity.

Ease of maintenance and cleaning is also crucial for ensuring consistent operation. Machines that are difficult to clean or maintain can cause costly downtime and potential contamination issues. High-quality machines are designed with user-friendly interfaces and components that can be easily disassembled, cleaned, and reassembled. Finally, manufacturers must consider the availability of technical support and after-sales services. Partnering with reliable pharmaceutical equipment manufacturers ensures access to comprehensive maintenance plans, training, and troubleshooting assistance.

Benefits of Using Advanced Pill Counter Machines

Modern pill counter machines provide several advantages for the pharmaceutical industry seeking to improve their production lines. One of the most adopted features is accuracy. Automated systems do not make mistakes, and pills will be counted with all the accompanying features so that the right dosage is always available. Aside from accuracy, automated pill counters provide another primary feature which is efficiency. The ability to count pills at a high rate means that large batches of pills can be produced faster, which in turn improves productivity levels.

The automated integration of pill counters with other equipment augments efficiency. Machines made by professional Pharmaceutical Equipment manufacturers can easily be incorporated into existing Production Line systems, which optimizes the process and minimizes system idle time. Modernized pill counter machines offer improved collection of data as well as monitoring of all processes. Many modern systems are equipped with monitoring capabilities that follow various performance metrics, detailing reports, and surmising possible issues before they halt the productivity rate.

The safety and hygiene policies are also an advantage. The need for manual counting is eliminated, which decreases the risk of contamination with the use of automated pill counters. This is critical for pharmaceutical products that need to be handled in a sterile manner. Additionally, sophisticated pill counters are made to conform to strict regulations so that manufacturers remain compliant with industry requirements. By working with reputable pharmaceutical equipment manufacturers, these businesses can improve their quality control and avert expensive non-compliance problems.

How to Choose the Right Pill Counter Machine

It is critical to pay attention to numerous critical factors when selecting counters for pill machines. This decision is pivotal, which means the assessing process should cater to your specific manufacturing requirements. Let us explore some effective strategies to help counter the problems faced when choosing a pill counting machine. Machines that process pills have different speeds and capabilities which directly address manufacturer’s requirements. It is important to determine your production capacity to avoid buying a machine that’s further ahead of high-speed line capabilities. Efficiency is crucial, so you should make your estimations as precise as possible.

Once process capabilities are defined, the type of pills to be counted should be assessed. Either way, the counter for the pill should not only be able to handle the material, but also the form whether it is a tablet, capsule, or other solids suitable for dosage. Machines that allow for flexible settings regarding the size, shape, and type of material enhance functionality. Last but not the least, the principles that involve other machines in the production line are just as important. A screw type automatic dispenser is for multi-component capsules and is best suited to work with tablet fillers since they share ideal principles of operation. Avoiding incompatibility between devices enhances production workflow and helps mitigate halts or break down in productivity.

Another pivotal factor is ensuring accuracy and convenience in maintenance. It is worth pointing out that high-grade machines by leading suppliers of pharmaceutical machines are expected to meet such a requirement, hence need to be serviced. Maintenance and repairs need to be simple to understand and easy to accomplish with clear instructions. Parts of the machine should be easy to obtain for quicker and more efficient replacements. And finally, serviceable parts should be easy to reach. Moreover, established suppliers offer reliable support while in need for something post sale as well. This extends to purchasing services, after sale maintenance, as well as servicing the machinery.

Conclusion

For boosting production efficiency, accuracy, and regulatory compliance, selecting the appropriate pill counter machine is crucial. Pharmaceutical companies that purchase high-quality equipment from reputable pharmaceutical equipment suppliers are likely to improve their manufacturing processes significantly.

The ideal machine must provide accurate counting, fast operation, compatibility with other production line equipment, and easy serviceability. Partnering with credible expert pharmaceutical equipment manufacturers guarantees the necessary industry-specific standards and high output quality. Contact us for more details .

Ensuring your company impressively meets output requirements and prudently selecting a suitable machine leads to enhanced productivity, improved product quality, and acceptable long-term profitability. Investing in a robust pill counter machine is arguably one of the most important steps to maintain competitiveness in the pharmaceutical industry.